STPs are crucial to human society and the environment’s well-being in their entirety. As the name suggests, these plants treat sewage water and cleanse it before it is released into water streams, rivers, etc., or reused in any form. But what exactly does an STP do, and how do the concerned authorities ensure its efficiency? Let’s delve into a few aspects of STP operation and maintenance.

What is an Sewage Treatment Plants?

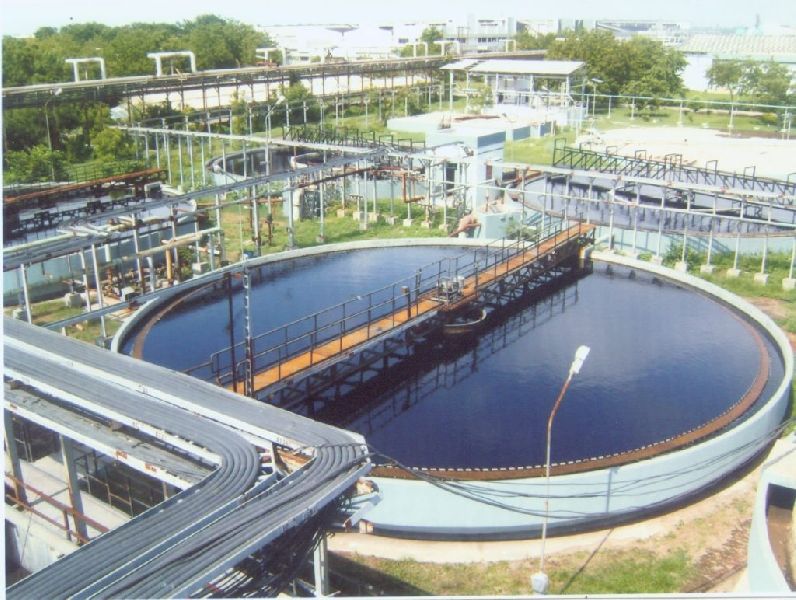

Sewage Treatment Plant treats wastewater/sewage, breaking it down into a cleaner effluent that can be safely reused or released. STPs are crucial because they help maintain groundwater balance, prevent the spread of diseases, and curtail environmental degradation. In the residential context, STP-treated water can be used for washing cars, gardening, construction, etc. It helps reuse water and avoids water scarcity.

How Does an Sewage Treatment Plants Operate?

STP works in four phases. Let’s overview each.

- Preliminary Treatment

Preliminary treatment involves removing tree branches, figs, plastic wrappers, bottles, and various other solid materials.

- Primary Treatment

Primary treatment takes place in a sedimentation tank that lets organic and inorganic solids settle at the bottom. At the same time, lighter materials, oil, grease, etc., float to the top with the help of skimmers. This is a crucial phase as it helps remove about 55-60 percent of solids. The remaining water moves to the next step.

- Secondary Treatment

Secondary treatment involves secondary clarifiers separating biological floc from the liquid via aerobic biological processes. It is done through indigenous microorganisms that consume biodegradable soluble contaminants. The stage helps clean about 90 percent of the water as solids and other pollutants are cleared during the primary treatment.

- Tertiary Treatment

This is the stage where nitrogen, pathogens, and other inorganic compounds are removed. It involves the chemical disinfection of water via UV light or micro-filtration before it is released for reuse. The sludge is then treated in digesting tanks with the help of anaerobic bacteria. The former can be used as a fertilizer.

What is Included in Sewage Treatment Plants Maintenance?

Maintenance is essential to maintain the STP’s efficiency. While low-quality STPs need frequent maintenance, high-quality STPs also aren’t devoid of maintenance, although not as frequent. However, the latter also requires de-sludged and servicing at least once a year. After the desludging process, the plant should be refilled with water so that internal and external pressure is balanced. STP operators and maintenance professionals must prevent the entry of water, as it could wash out all the bacteria and result in flooding.

STP maintenance includes checking the following.

- Replacing mechanical components as required

- Inspecting diffuser for bubble

- Replacing diaphragms and valve boxes

- Checking the color and smell of biomass

- Inspecting the final effluent quality

- Performing damage repair across all chambers

- Inspecting air filters and pipes

- Reviewing and ensuring the integrity of the lid seal

- Providing efficient and unobstructed blower and ventilation

Are you looking for STP operation and maintenance experts? Partner with CHFour. We are reliable STP manufacturing, operation, and maintenance professionals with years of experience and a proven track record within the STP space. Call +91 8055573883 or write to us at info@chfour.net to know more.